Clients: Lara and Terence Stevens-Prior

Project: 4-bedroom house, with pool, in Mission Bay

In this series, we take a fly-on-the-wall look at the progressive stages of a Box™ build

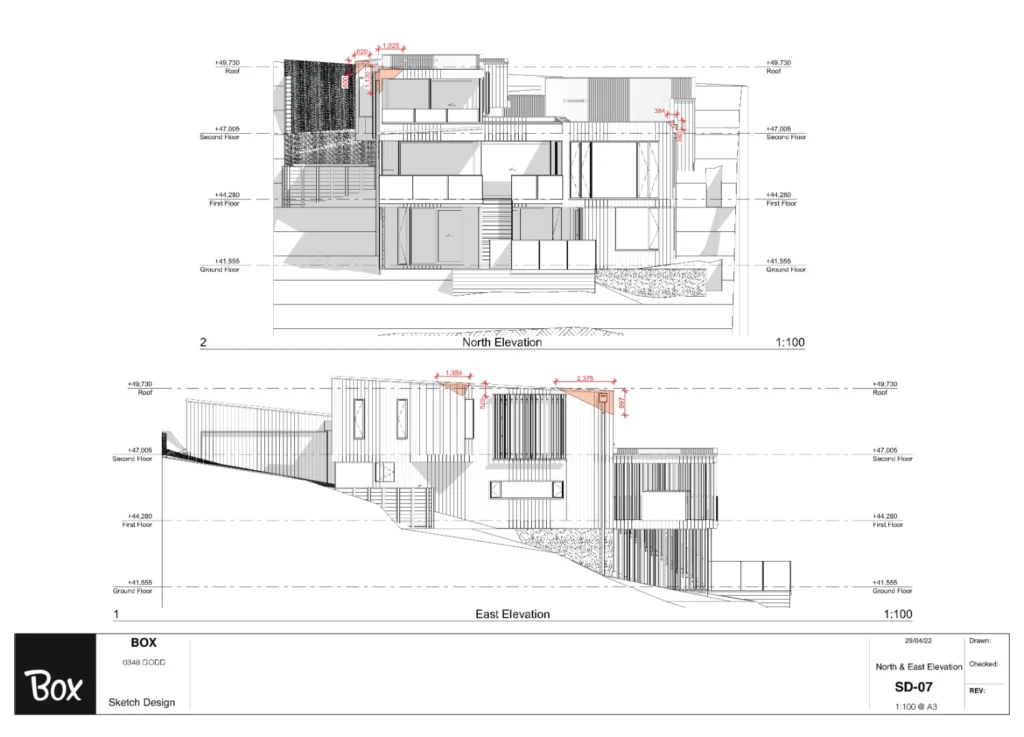

Details, details, details. It’s what Matthew Chamberlain, who works as a lead on our technical drawing team, excels at. Before construction, it’s Matt’s job to draw up the plans to a level that will satisfy the authorities to grant building consent. Then, during construction, he liaises with the builder if there are questions about the drawings or if situations that require his input crop up. Which, when you’re dealing with thousands of parts and products, they usually do. If a variation to the design is made, the drawings need to be changed and passed on to the building inspector to be signed off.

On this project, Matt is in almost daily contact with builder Dave Waugh. The latest issue surfaced when the roofing manufacturers got in touch to say that, due to the narrowness of the streets in the neighbourhood and the steepness of the section, they couldn’t physically deliver the 17-metre lengths of roofing sheet for the mono-pitch that was initially specified.

With shorter sheets a step-joint in the roofing was required. So, Matt and Dave got together to work out where this join on the first-floor roofing would be best placed to render it all but invisible, keeping the look crisp and seamless. Then Matt had to detail the waterproofing solution in updated drawings.

In the office he uses Archicad, a computer-aided drawing programme that allows exacting precision, but what he most enjoys is the interaction with Dave, and the chance to make a real difference to a job. That opportunity came at Godden Crescent when several exposed steel supports on the covered back deck – a lovely spot for a barbecue lunch – arrived from the fabricators with pre-drilled holes that were unsightly. Waiting for new posts would have meant holding up the job for months. Matt, Dave and design manager Tony Borland-Lye put their thinking caps on and came up with a plan to wrap the post where the hole would be visible in the same vertical metal that features on the cladding. It all ties together nicely and the clients love the new look.

From practical solutions, such as widening the internal gutters and beefing up the size of the downpipes to futureproof the design in terms of climate change, to working out a slightly different pitch for the raked ceiling that was the flow-on effect of this alteration, Matt, (who first wanted to be a fighter pilot before he realised New Zealand doesn’t have many planes), is involved in the nitty gritty. If Dave has a question about how the beams intersect or the joists are laid out, he turns to Matt for clarification. And having these two in the same team makes the process that much more seamless.

Now that the job has reached the stage where the roof is going on, there’s a lot to talk about. But as this structural side is completed, and the cladding begins, there’ll probably be fewer queries. Still, Matt gleans great satisfaction from the integral role he plays. The clients may be excited that, with the roof going on, the house envelope now has a hat, but so is he.

Being at Box™ means he gets to see a job through from start to finish; he gets to walk on the land and experience the end result. He has a real hand in helping our clients realise a dream. And that feels good.